|

How

to repair a stock crack.

Written by martin08 ("Matt") of the

forums

Disclaimer!!! Normally, I don't mess with restoration much. But I will

be shooting this one when it is done, a Reising M50 submachine gun,

once the final NFA approval arrives. Meanwhile, the registered owner

has allowed me to take possession of the stock for the necessary repair

work for a crack in the wrist. (sometimes this is allowed to preserve

the rifles so it may still be fired and used.)

My goal was to preserve the outward appearance of the stock (it's

really quite nice), without utilizing crosspins, but performing a

strong and permanent repair which would allow me to fire the gun

without doing further damage.

I had never attempted a stock repair of this magnitude, but I was

confident that I could gather the proper materials to have on hand for

performing the time sensitive task.

Following are a few pics of the stock/crack before repair. It appeared

on top of the stock wrist only, about 3-3/4" in length. And although

there is a shadow for the stock inletting picture, the crack protruded

downward approximately 1" at the rearmost inletting.

The Repair

To begin, I went ahead with an epoxy/dowel repair, learning as I went

along. I did make what will be a very serviceable repair, but also made

a critical error which will be explained later.

1. I selected a 5/16" dowel, and purchased a decent wood clamp and long

shank 5/16" drill bit.

2. With the stock clamped to close the crack, I began with a smaller

3/16" bit which enabled me to better locate a starter hole for the

larger bit.

3. To ensure proper depth for drilling, the tool bit was placed along

side for the length of the crack, and marked with a piece of tape. As

the crack emanated from the center of the stock at the rearmost

inletting, and traveled rearward and slightly to the right, I needed to

use my best judgement when drilling to follow the wrist and crack

angles, and without breaching the exterior of the stock. Drilling was

performed with the clamp in place, and to the depth which was marked on

the drill bit. Compressed air evacuated the sawdust from the hole.

4. The crack could then be prepped for optimal adhesion of the epoxy by

cleaning any interior oils/grime with acetone. With the clamp released,

I used a medicine syringe for application, and then an empty syringe to

force air into the crack for drying. The application of fast

evaporating acetone revealed the full length of the crack, as it stayed

wet for a little longer inside the crack.

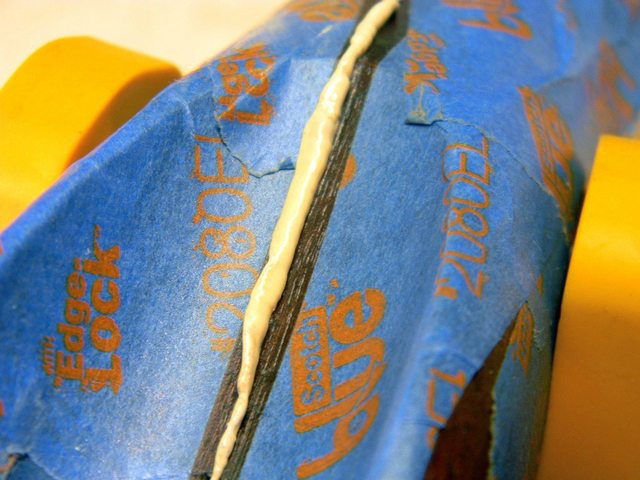

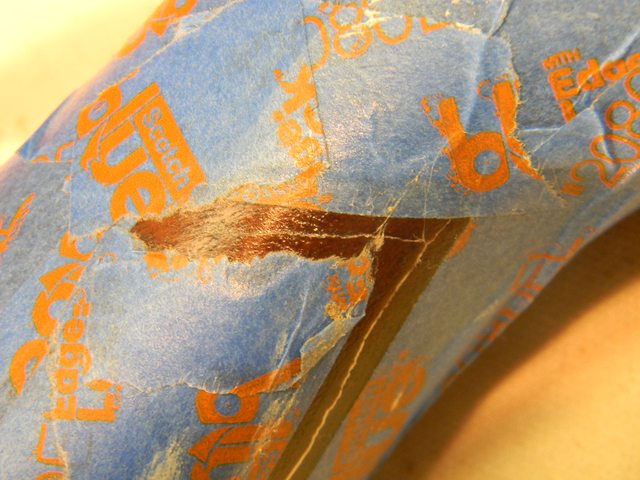

5. The stock could then be prepped to prevent a mess. I used general

blue painter's tape to mask around the crack. I applied a coat of paste

wax to the exposed area, using a q-tip with the cotton swab removed, so

no excess paste wax would be forced into the crack. The dowel was

inserted fully (dry), marked and removed to ensure the proper depth of

insertion, and corresponded closely to the drill bit depth.

5. The epoxy was then mixed. I chose a marine epoxy with a 60 min. set

up. This allowed for more working time and better flow when filling the

crack. A longer curing time also produces a stronger compound. An epoxy

with a short set up time will begin curing to quickly to properly flow.

The stock was then 'warmed up' with a hair drier to also aid with the

epoxy flow. I pulled the cotton swab off another q-tip to use as an

applicator to fill into the hole.

The amount of epoxy which I used would be very difficult to measure,

such as in milliliters. But suffice to say that the total glob was just

about the size of a small grape.

Here

is where I made a rookie mistake which affected aesthetics. I had

drilled a 5/16" hole and used a 5/16" dowel. I neglected to account for

the thin film of epoxy which would surround the dowel when inserted,

and upon reapplying the clamp, the crack would not fully close. Next

time, I will lightly sand the dowel to diminish the diameter - just

enough so that clamping would close the crack more tightly.

6. The dowel was then inserted, acting as a piston and forcing the

epoxy to evacuate the drilled hole, and flow into the crack. As the

epoxy is somewhat thick, it built up a hydraulic pressure, and the

final 1/2" of dowel insertion needed some assistance with a hammer,

stopping when it reached the depth mark on the dowel. The clamp was

then reapplied.

7. While the excess epoxy was oozing from the crack, I simply wiped it

away with a cloth, and kept wiping for about twenty minutes, until it

stopped oozing. Then, whether it made a difference or not, I just

rubbed some of the sawdust over the crack, penetrating only the

outermost exposed compound. The entire project was then allowed to rest

for 2-3 hours

8. After allowing plenty of time for the epoxy to initially set, the

masking tape was removed. The acetone came in handy again to soften and

remove an epoxy finger print smudge which I didn't see earlier. A small

amount of the epoxy which worked its way under the tape near the

insertion point was CAREFULLY chipped away with the edge of my pocket

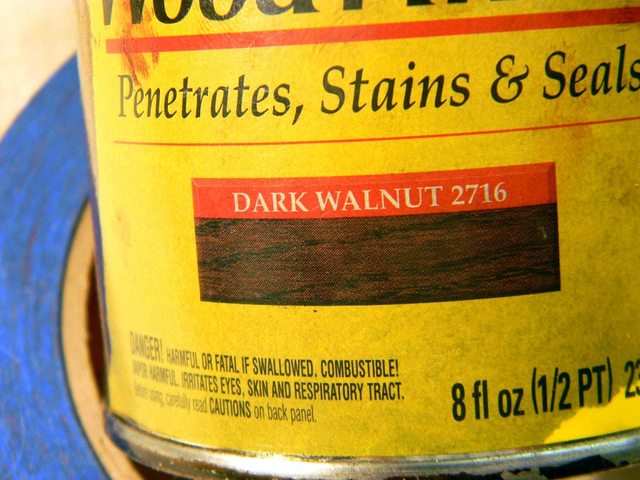

knife. Walnut stain was then applied to the exposed epoxy/sawdust

layer. And the then the project was allowed 24 hrs to fully cure, while

still clamped.

Had I slightly diminished the diameter of the dowel before insertion, I

would bet that the repair would be barely visible. But as it stands,

the repair is done, and likely quite strong. I will need to mate the

submachine gun action with the stock to perform enough relief by

removing just enough wood at the rear stock inletting, so that the rear

trigger housing lug will not contact the stock when firing and cause

another crack.

9. The clamp was removed, and the entire area buffed with a cloth.

Again, not perfect, but plenty serviceable now.

Thanks for looking on!

An excellent article written by martin08 ("Matt") of the

forums https://russian-mosin-nagant-forum.com

|